Rubber paving

Rubber paving

Rubber paving is made from recycled tires and has become a popular trend as an alternative to traditional types of applications, due to its permeability, flexibility, durability and non-slip properties. The rubber paving solution is an affordable investment guaranteed against cracking, which has demonstrated exceptional resistance to the extreme climates of Western Canada for over 20 years.

Read more

This innovative application, mixed and poured-in-place, is composed of recycled tire granules and an industry standard urethane-based binder. This mixture can be applied directly over a new gravel substrate or over the old cracked or uneven surface, eliminating the expense of removing the existing surface. The result is an odorless application that hardens in 24 to 48 hours in which water does not puddle and ice does not adhere to.

Rubber paving is widely used for driveways, walkways, patios and play areas. It is also used for access ramps, playgrounds, bike paths and animal care flooring. This ecological application that eliminates the need to landfill approximately 10 tires per 100 square feet of surface, is installed by trained professionals for quality assurance and to ensure industry standards are being performed.

Rubber paving is widely used for driveways, walkways, patios and play areas. It is also used for access ramps, playgrounds, bike paths and animal care flooring. This ecological application that eliminates the need to landfill approximately 10 tires per 100 square feet of surface, is installed by trained professionals for quality assurance and to ensure industry standards are being performed.

RUBBER PAVING: RESIDENTIAL

- Driveways

- Walkways

- Play areas

- Patios

RUBBER PAVING: COMMERCIAL AND RECREATIONAL

- Access ramps

- Playgrounds

- Storefronts

- Walkways

- Water park floors

- Golf course paths

- Animal care flooring and stables

- Equestrian trailer floors and more

RUBBER PAVING: MUNICIPAL AND INSTITUTIONAL

- Handicap ramps

- Splash pads

- Walkways

- Bike paths

- Green alleys

- Playgrounds

Ecological

The installation of rubber paving prevents thousands of tires from going to the landfill. Each 100 shredded tires can create an average of 1000 square feet of surface area.

The use of 100% recycled tires also reduces the impact of CO2 in the air starting from the granulation process of the tires, to its artisanal method installation, with practically no heavy carbon emitting machineries. In addition, the porosity of the application allows water to penetrate the soil and carry out the natural process of the ecosystem filtering water down to the water table. This rubber paving application is the true definition of being respectful of the environment and leaving its ecological footprint, which would even be 100% worthy of a LEED credit (Leadership in Energy and Environmental Design).

The use of 100% recycled tires also reduces the impact of CO2 in the air starting from the granulation process of the tires, to its artisanal method installation, with practically no heavy carbon emitting machineries. In addition, the porosity of the application allows water to penetrate the soil and carry out the natural process of the ecosystem filtering water down to the water table. This rubber paving application is the true definition of being respectful of the environment and leaving its ecological footprint, which would even be 100% worthy of a LEED credit (Leadership in Energy and Environmental Design).

Durable

Unlike many other materials available on the market, the products used for rubber paving have shown superior durability. The applications have been tested in extremely hot and cold temperatures, and have been proven to withstand the harsh winters of Western Canada for over 20 years. Rubber is very malleable and therefore it can resist sudden changes in temperature, as well as ground movement during freeze and thaw cycles. Unlike asphalt and concrete, rubber applications will not crack and are less than half the cost of removing and replacing concrete. The rubber paving mixture of recycled tires with an industry standard urethane-based binder, will offer a minimum lifespan of 25 years if treated with care. In short, it will keep its original state for decades to come!

Low maintenance

Unlike concrete, asphalt and paving stones which require a lot of maintenance, rubber paving is virtually maintenance free. Spills can be easily cleaned up with soap and water. Oil stains do not penetrate the rubber, as the material is neither absorbent nor organic, which discourages the weeds from growing on the surface. No annual black sealants treatments required, because black is the natural colour of tires and will not fade. A black driveway deserves to remain black!

Permeable

The finished product allows water to penetrate the slightly porous surface, instead of forming large puddles. The porosity of the application also allows snow and ice to melt faster, rather than forming ice caps. In most cases, a permeable paving surface can contribute in preventing the problem of large water runoff towards city sewers and retention ponds, while also helping to prevent premature deterioration of the underground infrastructure systems. It is best for rainwater to perform its natural filtration process, just like when it falls on grass and it percolates back into the ground towards the water table ecosystem. In addition, when installed near a tree, the surface allows for water and oxygen to reach the roots.

Safe

Rubber paving applications have slip-resistant properties that can help reduce the risk of falls and injuries. The rubberized surface significantly reduces the shock impact on landing, which is why it’s often used as a safety surface in playgrounds. In addition, rubber products by nature are antibacterial and antifungal, thereby preventing the growth of bacteria and fungi, making it a safer and healthier option for the elderly or families with children or pets. The porosity of the application eliminates puddles of water in summer and makes it easier to remove snow and ice, as rubber is a material that does not freeze, similar to ice not adhering to car tires.

Flexible

Recycled tire crumb is mixed with an industry standard binder to create a flexible surface that prevents cracking and resists sudden temperature changes, as well as ground movement during freeze and thaw cycles. This unique advantage of rubber surfaces minimize the risk of cracking that is commonly seen with concrete and asphalt. Rubber paving is based on the same theory as a vehicle tire which can absorb the incredible impact of potholes at high speeds or remain stationary for months at a time while always maintaining its original round shape. Even at high temperatures, rubber is a material that maintains its density and can resist sagging compared to bituminous type surfaces.

.

.

Affordable investment

Rubber paving is an eco-affordable alternative that is a little more expensive than asphalt, but much cheaper than uni-stone pavers. It is more cost-effective than replacing an old surface with concrete, which compares most in durability. Modernize your surfaces with aesthetic resurfacing, which can be installed over virtually any type of existent surface. Unmatched in the paving industry, rubber paving will save you time, money and enhance the value of your property, as well as its assurance against cracking will give you peace of mind for years to come!

Convenient

In many cases, there is no use of heavy machinery, therefore less risk of damaging your landscape. If the substrate is adequate, rubber paving eliminates the costs and disruption associated with removing the existent surface. This eliminates the costs of replacing the substrate with traditional aggregate materials and reduces the impact on the environment. Installations will normally take one to two days on average and will cure within 24 to 48 hours. The application is incredibly tough and durable, but accidents may occur. The advantage is that the installer can simply extract the damaged section and reapply the new product to marry it with the existent surface and in most cases, the repair will be unnoticeable.

What is the difference between EPDM and recycled tire granules?

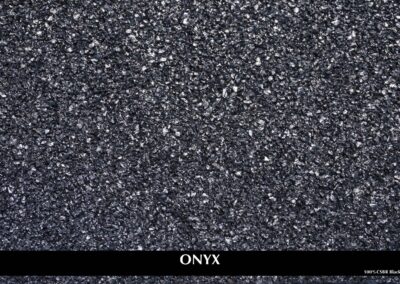

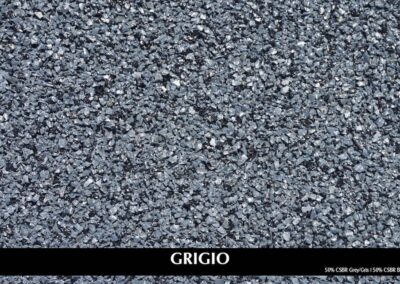

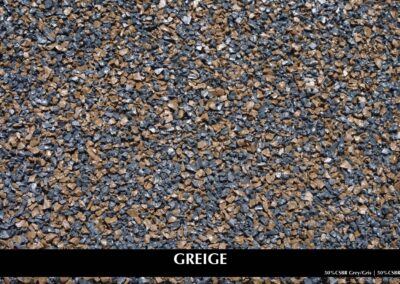

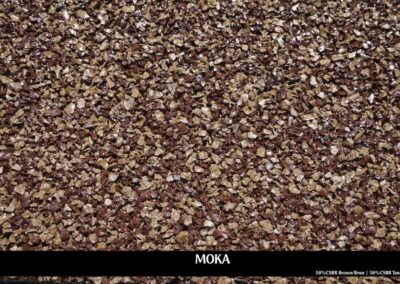

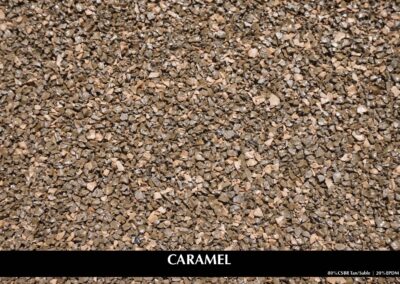

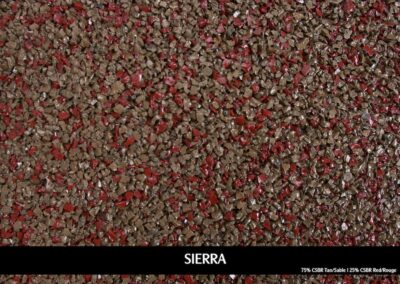

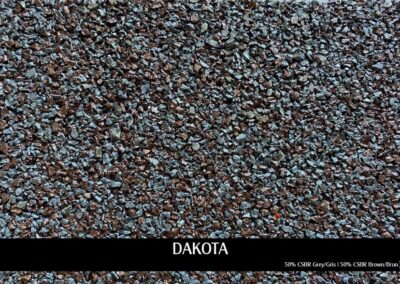

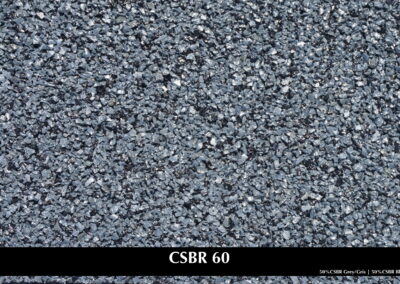

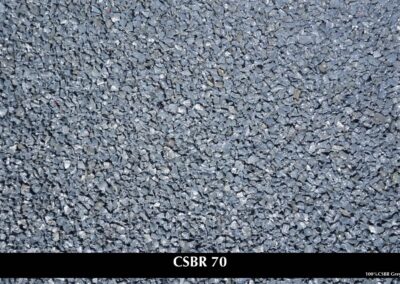

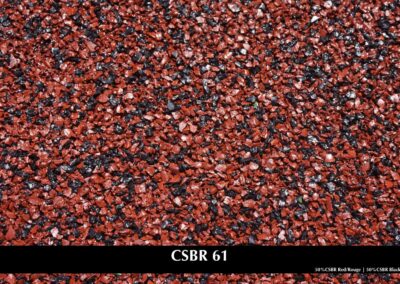

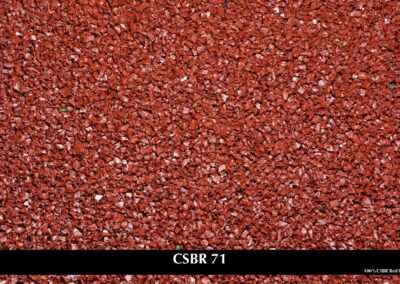

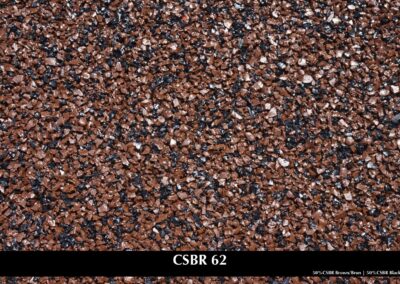

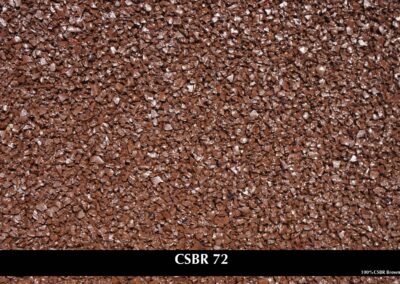

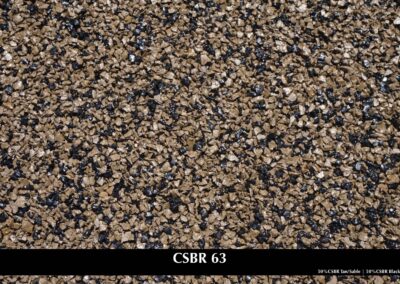

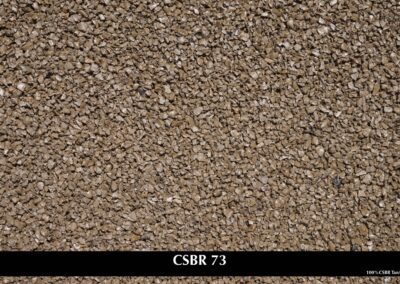

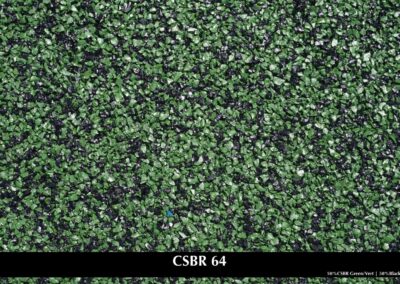

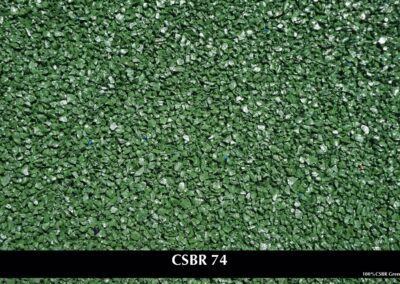

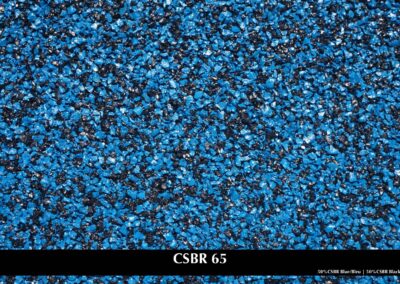

Recycled tire granules are usually sourced from a local shredding plant, while EPDM granules are made from virgin rubber, a synthetic material, which makes it a bit more expensive. EPDM has a wider range of colors from very light to dark and is typically used for resurfacing with a higher level of comfort in mind. The recycled tire is denser, which is why it’s more suitable for installations such as driveways.

Over what type of surface can rubber paving be applied?

Rubber paving can be applied directly over asphalt, concrete, paving stones, metal, roofing membrane and also on a gravel substrate. On the other hand, EPDM rubber surfacing absolutely requires a solid, non-granular substrate.

Where is rubber paving most commonly used?

Rubber paving is commonly used on driveways, walkways, patios and children's play areas. At the commercial level it is often used on playgrounds, water parks, stables and many other commercial and municipal spaces such as in parks and bicycle paths.

Can rubber paving be installed indoors?

Generally, rubber paving is not installed indoors with the exception of barns and animal care flooring where comfort and durability is sought after. For more standard indoor installations such as garage floors and fitness surfaces, EPDM rubber surfacing would be the better option.

Can rubber paving be installed directly on soil or grass?

No, it is absolutely necessary to provide at least a stable and well compacted gravel substrate.

Can rubber paving be installed directly on a wooden surface?

Since rubber paving is permeable to water, all wood surfaces must be waterproofed prior to resurfacing, otherwise the wood underneath will rot over time.

How should rubber paving be cleaned?

To simplify the task, we suggest using a leaf blower. For a more thorough cleaning in the spring, we recommend washing with a residential grade pressure washer. To remove stains, simply use a degreasing dish soap.

Can engine oil affect the rubber paving surface?

No, because the raw material of rubber paving is recycled tire, which essentially is a non-absorbent material. Thus, any oil stains will not be harmful on the surface and easily cleaned with a light rub of dishwashing detergent.

Does rubber paving require regular maintenance?

Unlike concrete, asphalt and uni-stone pavers which require a great deal of maintenance, rubber paving is practically maintenance-free. Only if deemed necessary, due to a high level of UV exposure, we recommend refreshing the surface with a clear coat to protect against potential drying out of the granules. This application is quite simple, once the product is provided, you could even apply it yourself.

How to remove snow on a rubber paving surface?

Remove the snow as you normally would! A plastic shovel is always recommended rather than a metal shovel. If you are dealing with a residential snow removal company, it is common for the blower tractors and trucks with shovels to be equipped with a plastic shield to prevent the metal edges of the equipment from scratching the surface. You can also use a snow blower as they usually have plastic pads on the bottom, otherwise teflon pads can easily be added.

How does rubber paving facilitate the snow removal?

Just like your tires which are designed not to adhere to snow and ice, the textured surface of rubber paving makes it easier to scrape and remove ice, compared to asphalt and concrete where the bottom layer of ice adheres the surface with fierce tenacity.

How does rubber paving help prevent falls and injuries?

Rubber paving has a slightly porous textured surface, which provides superior slip-resistance compared to other surfaces. Snow melts quicker and water does not accumulate due to the permeability of the surface, therefore reducing potential black ice, which is the cause of many falls and injuries.

Can salt or de-icers damage a rubber paving surface?

No, you can safely use salt or any type of eco-friendly de-icers.

How does rubber paving resist in winter?

Rubber is very malleable and therefore resists temperature changes, as well as ground movement during freeze and thaw cycles. The application has been proven to withstand the harsh winters of Western Canada for over 20 years and Eastern Canada for the past 10 years.

What is the lifespan of rubber paving?

The main material in rubber paving is recycled tire crumb, practically indestructible, mixed with an industry standard urethane-based binder. If treated with care, this composition is very durable and has a lifespan of at least 25 years.

If the surface gets damaged, is it repairable?

Yes, even though rubber paving surfaces are incredibly tough and durable, accidents can happen. The installer simply needs to extract the damaged section and reapply new product to marry it with the existent surface.

How long does it take to install a rubber paving surface?

Usually, installations take between 1 to 2 days, unless otherwise specified for large projects. The first stage is the preparatory work of the existent surface and the second stage is the pouring of the product. In some cases, both stages could be done on the same day.

Are there any constraints in the installation of rubber paving?

Unfortunately yes, rubber paving cannot be installed in the rain. The surface must be dry, with the presence of some atmospheric heat during installation and night temperatures that do not freeze. However, there is no risk if it rains afterwards, once the product is installed and the work is completed, as water is only an accelerator in the curing process.

How long does it take before I can walk or drive on the new surface?

Rubber paving hardens in the presence of heat and humidity. Under ideal conditions, allow 24 hours before you can walk on it, and at least 72 hours before parking a vehicle and at least a week before parking a truck or heavy vehicle.

Does rubber paving have an odor?

The application is practically odorless. Depending on the weather conditions, during the installation you will be able to capture a scent which will fade quite quickly in the following days.

If the recycled tire is black, how is it possible to have a colored application?

Recycled tire granules are processed through a factory coating coloring process. Followed by the application of a clear protective coating which encapsulates the color for superior tensile strength, ultimate UV resistance, increased surface durability with better impact and dry steer resistance.

Can rubber paving withstand a heavy weight vehicle?

Yes, you can drive over the pavement with a heavy weight truck for the occasional delivery, but not on a daily basis. Rubber paving applications cannot withstand commercial type traffic.

Can an RV remain stationary on the rubber paving?

Yes, because rubber paving can withstand the weight of a heavy vehicle and when the vehicle is parked, rubber is a material that does not decompose in the heat. It is best compared to the firmness of concrete, rather than compared to asphalt which tends to create divots when the bitumen heats up.

Does rubber paving retain heat or reflect UV rays?

It goes without saying that the lighter shade options reflect UV rays more than a black surface. Rubber paving retains less heat than conventional surfaces due to its permeable properties. This allows air and water to flow through the pores of the surface, allowing for a much faster comfort temperature recovery.

Where does the water flow once it enters the pores of the surface?

Generally, the water finds the path of least restriction to go towards a downhill slope. If applied over a gravel substrate, the water percolates and filters through the ground towards the water table.

If rubber paving is permeable, can the water passing through it in winter adversely affect the surface?

No, because the application maintains elasticity and flexibility at all times and in all weather conditions. The micro-frost that might form in the pores of the surface would be impossible to expand enough to the extent of potentially cracking the surface.

If installed as a resurfacing method, how does the overlay meet with the edges of a sidewalk or the existent elevations?

Generally, each installation requires some preparation and special attention along the edges of current elevations. The ideal method is to recess part of the existent surface by cutting or grinding to lower the height of the current surface to match the desired height. The transition is often so smooth that not even a lynx's eye will notice it!

When applied in a stable or horse trailer, what happens to the urine?

The rubber surface can be sealed to make it impermeable so that the urine remains on the surface. However, if there is presence of drains, it is not necessary to seal it, because when washing the surface the water seeps into the product and then flows in the direction of the current slopes towards the floor drains.

How is rubber paving installed?

The installation of rubber paving is an artisanal process, similar to that of pouring concrete. The cold mix consists of 100% recycled tire crumb combined with a urethane-based binder. The components are mixed on site in a mortar mixer. The craftsman then installs and spreads the granular mixture evenly over the existent surface. Once the product is spread, the installer can either compress the application with a trowel or run a grass roller to close any open pores and make the entire application even and seamless to an average thickness of (1”) one inch. We invite you to watch the video of the installation process.

Could we install rubber paving ourselves?

Taking into account the artisanal nature of the application, anyone wishing to install this type of product should pass a minimum of training to understand the peculiarities of the product and ensure proper installation. If you are interested in a training, please do not hesitate to contact us.

How much does rubber paving cost?

Rubber paving is an eco-affordable alternative that is a little more expensive than asphalt, but much cheaper than uni-stone pavers. It is more cost-effective than replacing an old surface with concrete, which compares most in durability. The cost will vary depending on installation factors such as area dimensions, type of installation, preparation required, and finishing. Unmatched in the paving industry, rubber paving applications will save you time, money and enhance the value of your property, as well as give you maintenance-free peace of mind for years to come! Do not hesitate to find a contractor in your area for a pricing request.